Endurance Drones

Long endurance drones provide a flight time greater than that of typical quadcopters and small fixed-wing UAV (unmanned aerial vehicles), which typically can only stay in the air for times ranging from half an hour to a couple of hours. Their enhanced flight time allows them to cover long ranges, unlocking a variety of applications.

Propulsion

Long endurance fixed-wing and multirotor UAVs need to be large enough to carry the propulsion systems required to provide the additional flight time. Batteries have a relatively low energy density, meaning that they deliver less flight time for the extra weight they take up compared to other power sources. Endurance UAV therefore typically require an additional form of power, such as a hydrogen fuel cell or petrol-powered internal combustion engine. These drones may also utilise a hybrid power system that combines batteries with another power source.

Types

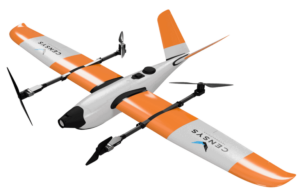

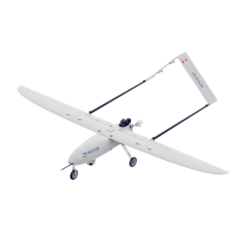

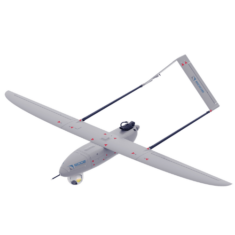

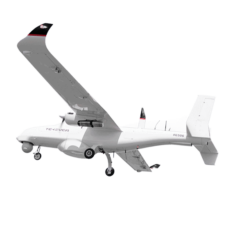

Long Endurance Fixed Wing UAV

Small fixed-wing UAV design typically enables greater endurance than quadcotor drones, with the ability to cover further distances, faster. Small fixed wing UAVs can be launched by hand, whereas larger fixed wings are usually launched via catapult or runway. Hybrid fixed-wing UAVs combine VTOL (Vertical Take Off and Landing) capability with fixed wing design, enabling long flight times with minimal launch footprint.

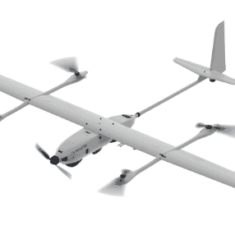

Quadcopters, Multirotors & Unmanned Helicopters

Endurance multirotor drones require a hybrid power system or hydrogen fuel cell, as batteries alone are too bulky to provide significant mission endurance. For long-range applications requiring the manoeuvrability of rotorcraft, unmanned helicopters are more common due to their superior carrying capacity.

Tethered UAVs

Tethered drones are ideal for long endurance applications that only require the aircraft to remain in one spot, such as persistent surveillance, event security and communications relays. Tethered drones are powered from their ground station, which may be connected to a generator or mains power supply, effectively giving unlimited flight time.

High and Medium Altitude UAVs

HALE (high altitude long endurance) and MALE (medium altitude long endurance) platforms tend to be fixed-wing UAVs. MALE UAVs fly at altitudes of 10,000 to 30,000 feet, while HALE drones can operate even higher and are often capable of faster speeds. Both types are used by militaries for applications such as persistent ISR (intelligence, surveillance and reconnaissance) as well as providing strike capabilities.

Pseudo-Satellites

HALE UAVs may even operate in the stratosphere. These drones, also known as HAPS (high-altitude pseudo-satellites), can utilise solar power more effectively, as they are operating far above the clouds, and use solar panels during the day to recharge batteries that can power the aircraft at night. HAPS UAVs can stay aloft for days at a time, and one of the goals of the industry is to produce a platform that can fly persistently, only needing to descend every year or so for maintenance. Applications for this emerging drone technology include long-term surveillance, as well as the provision of mobile phone and internet connectivity to areas that were previously lacking.