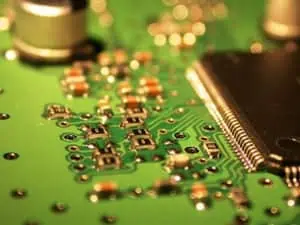

PCBs (printed circuit boards) connect electronic components together using conductive tracks and other structures in order to realise an electronic design. The conductive features are typically chemically etched out of copper laminated onto or between layers of non-conductive substrate. Common substrates include various forms of glass epoxy, as well as cotton paper impregnated with resin.

Drone PCB Design

PCB Fabrication and Assembly by MPL Inc

PCB design is done via CAD software. The output files from this software are used to fabricate the PCB, and this process includes tasks such as etching and removing copper, drilling holes, and adding protective coating and finishes.

PCBs may be designed for a wide variety of drone and robotic vehicle subsystems. These may include the speed controller that controls the RPM of the drone motors, power distribution systems, autopilots, and flight controllers. Drone PCB may also incorporate components essential to the operation of the aircraft such as IMUs (inertial measurement units), GNSS receivers, and power amplifiers for communications systems

PCB Fabrication & Assembly

PCB assembly is the process of populating the board with components. This can be done by hand, but for most production runs is usually done automatically via machine. After the PCB fabrication and assembly process is completed, the board will usually undergo testing, which can be performed manually or automatically depending on the complexity of the tests required.

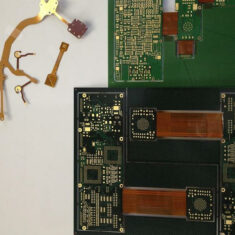

SMT PCB & Flex PCB

Flex PCB by San Francisco Circuits

Components are attached to the PCB by soldering. Larger components are usually through-hole, attached by passing the component legs through the board and soldering on the other side. Smaller components use SMT (surface mount technology) and are soldered directly to one side of the board.

PCBs for drones and robotics may have to conform to size and weight constraints, or fit into awkwardly-shaped spaces. Flex PCBs, which are printed on a flexible material, can be an ideal solution to such design requirements. Flex PCBs may also be used as an alternative to heavier and bulkier wiring and connector harnesses.