Rigid Flex PCB

San Francisco Circuits (SFC) provides rigid flex printed circuit board services with turnaround times as fast as 48 hours, using only trusted manufacturers.

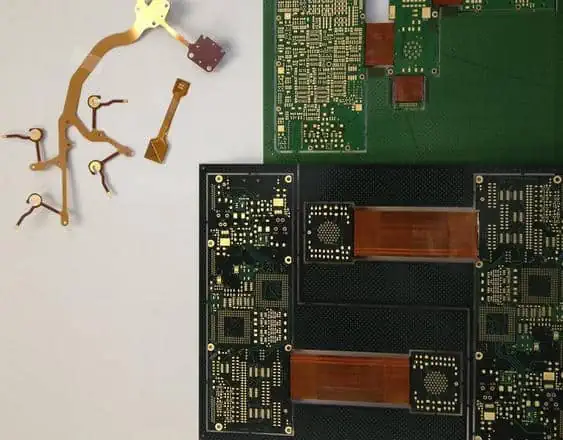

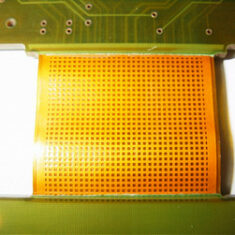

Rigid flex PCBs consist of multiple layers of flexible substrates attached to one or more rigid boards, with the substrates designed to be in a constant state of flex. These PCBs allow developers to create circuit board designs in a 3D space, ensuring greater efficiency, eliminating many of the requirements for solder joints, connectors and fragile wiring, and making it easier to conform to the space within the application's package.

SFC can provide rigid flex PCBs for mission-critical drones and robotics, including military unmanned systems.

| Specifications | Capabilities |

| Drill to copper – Outer layers | 8 mil |

| Drill to copper – Inner layers | 10 mil |

| Copper Thickness | 0.5 oz - 4 oz |

| Minimum Hole Size | 0.004" |

| Minimum Trace/Space | 0.003"/0.003" |

| Minimum Pitch | 0.5 mm |

| Copper to board edge | 0.007" |

| Coverlay Opening | 0.003" |

| Coverlay Web (Kapton) | 0.006" |