Plettenberg has authored the following article that explains why inrunner BLDC (brushless direct current) motors are growing in popularity for UAV (unmanned aerial vehicle) applications.

What is an inrunner BLDC motor?

Before we dive into the details of brushless direct current (“BLDC”) inrunners, it should be established that the basic physics behind in- and outrunner BLDC motors are principally the same. Both motor types use permanent magnets, windings made of magnet wire and electrical steel laminations. The magnets are located at the rotating part (“rotor”) and the windings are static (“stator”). The main difference between in-and outrunner is the location of the rotating part and therefore the mechanical design of the motor.

Before we dive into the details of brushless direct current (“BLDC”) inrunners, it should be established that the basic physics behind in- and outrunner BLDC motors are principally the same. Both motor types use permanent magnets, windings made of magnet wire and electrical steel laminations. The magnets are located at the rotating part (“rotor”) and the windings are static (“stator”). The main difference between in-and outrunner is the location of the rotating part and therefore the mechanical design of the motor.

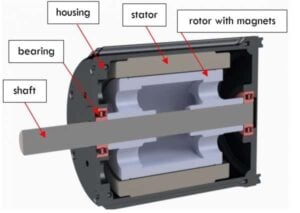

An inrunner BLDC motor has the turning rotor at the center of the housing. This implies that except for the shaft-end, all rotating parts are inside the motor. The stator is built around the rotor and fixed to the motor housing. The permanent magnets are located at the surface of the rotor or are buried in the rotor. The shaft is connected to the inside of the rotor, usually with a connecting element made of aluminum. The rotor of a typical inrunner is much smaller in diameter compared to an outrunner of the same motor diameter. From the outside, the inrunner looks comparable to AC or brushed DC motors.

Inrunners have several advantages relative to outrunners. First, cooling is much easier and more effective, due to direct contact of stator and housing, even with a fully closed motor design. This allows for high protection class (IP rating). The compact design of rotor, shaft and bearings, in combination with the closed housing, make the motor very robust and ideally suited for use in harsh environments. The compact design also results in a very smooth-running of the motor. Inrunners can also be integrated into the final application (i.e. fully closed housing), providing additional protection, reduction in weight, improved aerodynamics and better design look. The inrunner is also preferred for applications with high power requirements such as heavy-duty drones or maned systems. Generally, inrunners have a lower moment of inertia, which makes them ideal for highly dynamic applications such as multicopper, resulting in a higher overall efficiency of the final product.

Historically, the inrunner motor has also had some disadvantages vs. outrunners. One of the main disadvantages was the requirement of a gear box for some applications to reduce RPM. This made the whole system much heavier and more costly. Further, inrunners had lower torque, which made them less suited for application with large rotors. If the inrunner is manufactured with closed design, the motor is more robust, but also heavier as compared to an outrunner. Lastly, inrunners are more difficult to manufacture, making them somewhat more costly to produce.

Historically, the inrunner motor has also had some disadvantages vs. outrunners. One of the main disadvantages was the requirement of a gear box for some applications to reduce RPM. This made the whole system much heavier and more costly. Further, inrunners had lower torque, which made them less suited for application with large rotors. If the inrunner is manufactured with closed design, the motor is more robust, but also heavier as compared to an outrunner. Lastly, inrunners are more difficult to manufacture, making them somewhat more costly to produce.

What is an outrunner BLDC motor?

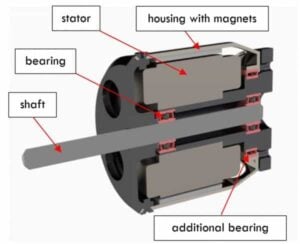

The outrunner BLDC motor has nearly all rotating parts on the outside. The outer case of the motor is the rotor and has the permanent magnets attached at the inside. The outer case is also attached to the motor shaft. The stator is located inside the rotor. The only connecting point of the stator to the outside of the motor is the mounting plate. Typically, outrunners are larger in diameter and smaller in length has compared to inrunners. Outrunners have several advantages relative to inrunners. The main advantage of outrunners is the lower weight, which makes them ideally suited for applications with weight limitations. The stator winding design is easier to manufacture, which makes the motor less costly to produce as compared to inrunners. Generally, outrunners have higher torque which makes them better suited for larger rotor applications. Lastly, the kV (RPM per Volt) is also lower.

The outrunner BLDC motor has nearly all rotating parts on the outside. The outer case of the motor is the rotor and has the permanent magnets attached at the inside. The outer case is also attached to the motor shaft. The stator is located inside the rotor. The only connecting point of the stator to the outside of the motor is the mounting plate. Typically, outrunners are larger in diameter and smaller in length has compared to inrunners. Outrunners have several advantages relative to inrunners. The main advantage of outrunners is the lower weight, which makes them ideally suited for applications with weight limitations. The stator winding design is easier to manufacture, which makes the motor less costly to produce as compared to inrunners. Generally, outrunners have higher torque which makes them better suited for larger rotor applications. Lastly, the kV (RPM per Volt) is also lower.

The outrunner also comes with several disadvantages. The design with inside stator and outside magnets leads to an unfavorable heat dissipation. As a result, the outrunner requires an open design with air flow cooling direct through the motor. In most designs, the housing is not equipped with an additional bearing. This makes the motor less robust and allows for e.g. dust and water to get inside the motor. It also means the motor cannot be manufactured with high IP protection class. Typical outrunners are lower in efficiency as compared to inrunners, especially at high RPMs, which mitigates the weight saving. Outrunners have a higher moment of inertia, which gets especially problematic in larger motor designs and for highly dynamic applications.

The outrunner also comes with several disadvantages. The design with inside stator and outside magnets leads to an unfavorable heat dissipation. As a result, the outrunner requires an open design with air flow cooling direct through the motor. In most designs, the housing is not equipped with an additional bearing. This makes the motor less robust and allows for e.g. dust and water to get inside the motor. It also means the motor cannot be manufactured with high IP protection class. Typical outrunners are lower in efficiency as compared to inrunners, especially at high RPMs, which mitigates the weight saving. Outrunners have a higher moment of inertia, which gets especially problematic in larger motor designs and for highly dynamic applications.

Why are inrunners growing in popularity for UAV applications?

Over the last years, inrunners have seen several technological advances, which have helped to overcome most of the disadvantages compared to outrunners. A good example of such innovation is the increased number of poles (up to 70) and a special redesign of the magnetic system. These adjustments allowed for an increase in torque density and lowering of RPM. It also reduced the need for iron and therefore reduced motor weight significantly. The kV was also reduced to the level seen with outrunners. With lower RPM, gear boxes are not required anymore for most applications, which reduced system cost and weight further. Innovation will continue to focus on improving thermal characteristics, increasing efficiency and reducing system weight, while retaining the high robustness of the motor.

Over the last years, the market for professional and heavy-duty UAV applications has grown significantly. For example, drones are increasingly finding use in applications in which certain objects or equipment is being transported and increased payloads are required. The same is true for unmanned ground vehicles and robots, which are increasingly taking over manual tasks and where heavy items need to be moved or lifted. UAVs also find increased use in harsh environments such as snow, desert or sea water operations, in which components need to fulfill highest IP protection class standards. Given the better heat dissipation vs. outrunners, inrunner motors can be manufactured in closed design, which allows for highest IP protection class. In addition, inrunners are more robust against shocks and other environmental forces. The thermal characteristics of inrunners often allow for a product design in which the motor is fully housed in a certain application. This allows for greater design flexibility as well as protection of the motor. Inrunners are also very well suited for larger applications requiring higher power, such as heavy-duty drones or maned systems, as they are easier to scale. The generally higher efficiency of inrunners also becomes very important in heavy-duty applications as longer operation times and increased reach become possible.

The technological advances highlighted above have reduced the weight and overall system costs significantly, making inrunners highly competitive for many UAV applications. Overall, it can be concluded that inrunners are often on par with outrunners in characteristics that have historically been disadvantages of inrunners. At the same time, inrunners have retained all their advantages. This makes inrunners a very suitable solution for many UAV use cases.