Circular connectors contain one or more pins or sockets within a circular housing. Due to their shape, they can group multiple contacts in a compact configuration, giving them an advantage for space-constrained applications such as UAVs (unmanned aerial vehicles) and other unmanned systems. They may also house multiple kinds of contacts, and transmit power, data, and signals of different voltages, thus doing away with the need for multiple connectors.

Omnetics Micro 360® Circular Connectors

Materials and Engineering

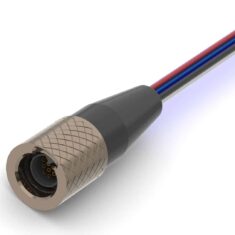

Circular connectors are constructed with plastic or metal shells. Metalized composite shells are also available, providing a lightweight durable option that will help reduce overall weight for SWaP-limited unmanned systems. Aluminium is commonly used in higher-end components and provides additional EMI protection. The shells are found in a variety of different forms, including panel mount, inline and right-angled. In addition to improving EMI performance, they may also provide strain relief for the cable.

MD801 Cinch Mil_Aero Circular Connectors

Ruggedization

Connectors used in harsh environments may require rugged construction to protect again water ingress, dust, shock, vibration and extreme temperatures. Relevant IP ratings for dust and water protection include IP64, IP67, IP68 and IP69K. MIL-38999 is a common standard for mil-spec connectors, although these may be too bulky for small drones and robotics, and miniature circular connectors may be required instead.

Nicomatic OMM Circular Micro Connector

Circular Push Pull Connectors

Circular connectors with a push-pull mating may be used when rapid engagement/disengagement is required, such as for battlefield or emergency use systems where parts may need to be swapped out or replaced as quickly as possible. Connectors may also have a screw-thread or bayonet locking mechanism to provide more secure mating and enhance sealing. Unique keying for mating plugs and receptacles may be used to prevent user errors such as cross-mating or mis-mating, which may permanently damage the connector or cause a system to malfunction.