Tyto Robotics explores the differences between different types of electric motors, comparing their efficiency for use in many industries and applications, including unmanned systems.

Electric motors are used in many industries and applications, and are essential for converting electrical energy into mechanical energy. However, not all electric motors are created equal when it comes to efficiency.

What is motor efficiency?

First, let’s define what we mean by motor efficiency. Motor efficiency is the ratio of output power to input power, expressed as a percentage.

It measures how effectively a motor converts electrical energy into mechanical energy. The higher the efficiency, the less energy is lost as heat or other forms of waste, and the more power is available for useful work.

The most common types of electric motors are DC motors, AC motors, and brushless DC motors. Each of these motors has its own advantages and disadvantages when it comes to efficiency.

DC Motor Efficiency

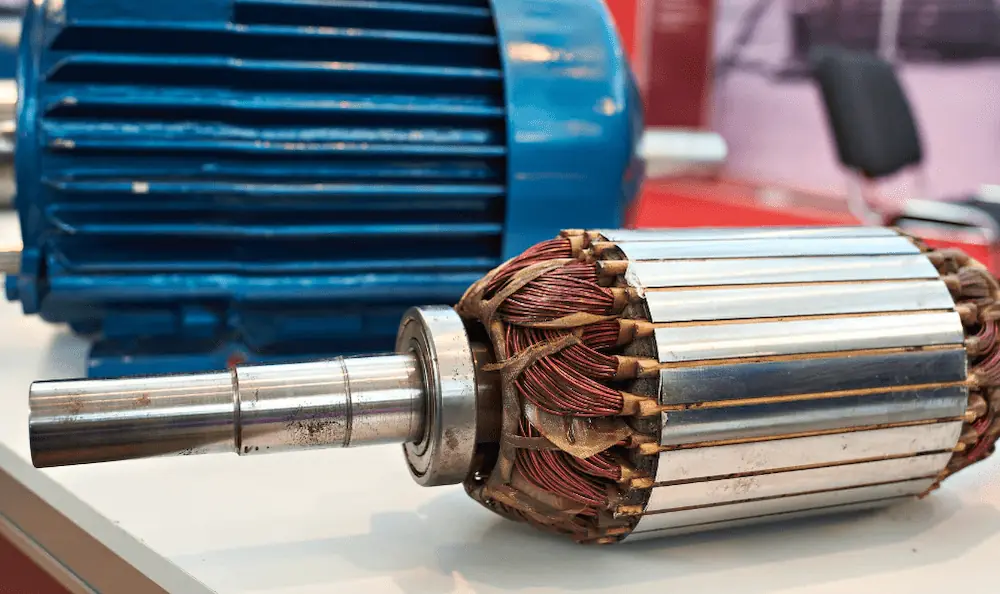

DC motors are the simplest type of electric motor, and they have been used for many years in a variety of applications. They operate by using a direct current to create a magnetic field that rotates the motor’s armature.

DC motors are known for their high starting torque and controllability. However, they are also known for their low efficiency, typically ranging from 50-80%.

This is due to the energy lost as heat in the motor’s windings and brushes.

AC Motors Efficiency

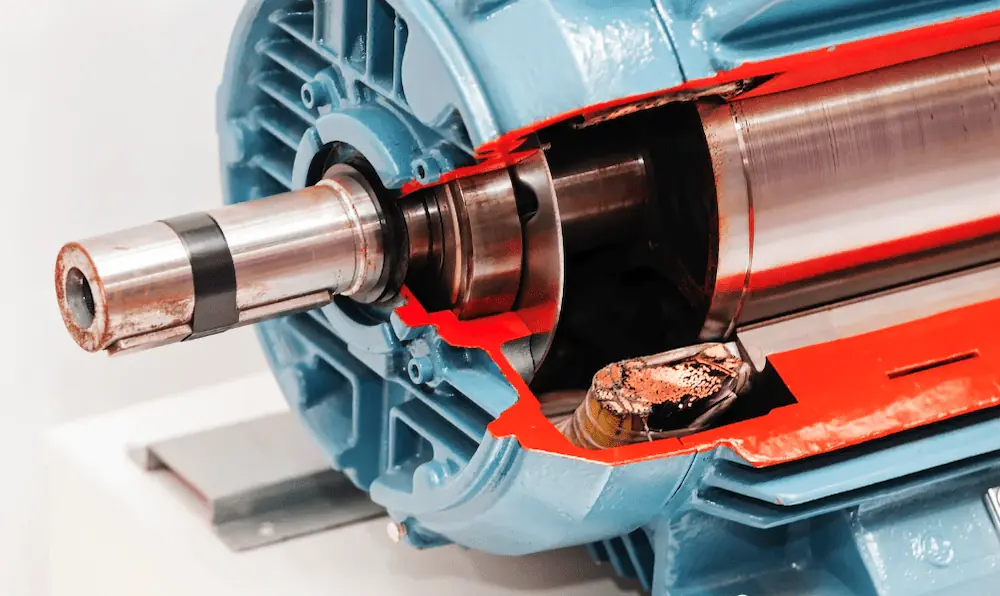

AC motors are more complex than DC motors but are more commonly used in industrial and commercial applications. They operate by using an alternating current to create a rotating magnetic field that drives the motor’s rotor.

AC motors are known for their high efficiency, typically ranging from 75-90%. This is because they don’t have brushes, which eliminates the energy loss associated with them.

However, AC motors are less controllable than DC motors, and their starting torque is usually lower.

BLDC Motor Efficiency

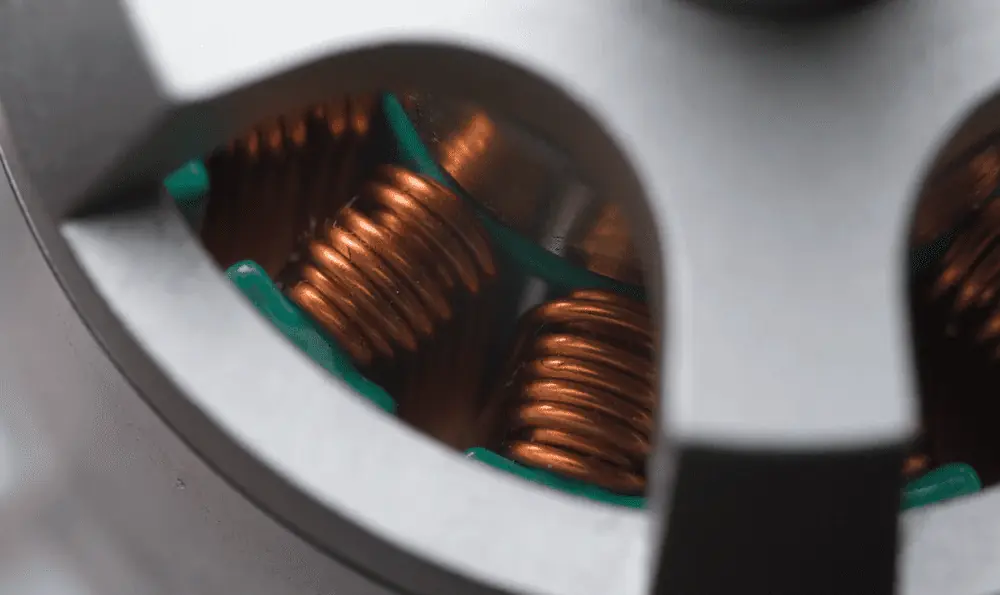

Brushless DC motors are a newer type of electric motor that combines the best features of both DC and AC motors.

They operate by using a permanent magnet rotor and an electronic controller to switch the current in the motor’s windings.

Brushless DC motors are known for their high efficiency, typically ranging from 80-95%. This is because they don’t have brushes and use electronic switching to control the current, which eliminates energy loss.

Brushless DC motors also offer high controllability and starting torque.

Conclusion

In conclusion, electric motor efficiency varies depending on the type of motor and its application.

When comparing the efficiency of electric motors, it’s important to consider the specific application and requirements.

DC motors have lower efficiency but high controllability and starting torque. AC motors have higher efficiency but lower controllability and starting torque. Brushless DC motors offer high efficiency, controllability, and starting torque, but are typically more expensive.

When choosing an electric motor, it’s important to consider the trade-offs between efficiency, controllability, and cost to find the best option for your specific needs.