Mejzlik Propellers and IAI (Israel Aerospace Industries) have released the results from the first phase of the CRAFT (Contra Rotating, Analysis, Fabrication, and Test) project.

The goal of the R&D project is to optimize the coaxial configuration for UAM (Urban Air Mobility) platforms considering both performance and acoustics, since these parameters contribute to and determine the success of a flight mission.

In addition to propeller safety and reliability, the propeller performance and the noise footprint are some of the most important parameters of a propeller. Noise is one of the biggest challenges with eVTOL (electric vertical take-off and landing) aircrafts operating around cities and urban areas, mainly due to public acceptance. These challenges also apply to smaller platforms such as drones and UAVs (Unmanned Aerial Vehicle) used for delivery or defense applications.

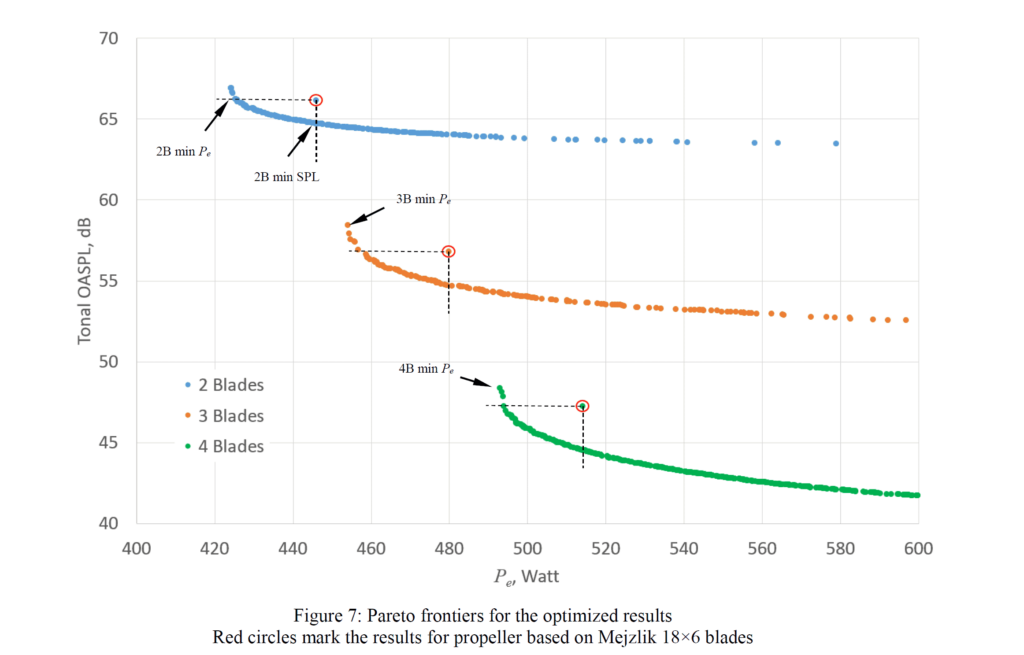

The first phase of the CRAFT project focused on a scaled-down SR (single rotating) propeller configuration under hover conditions, in order to optimize a propeller in terms of performance, acoustics, and the trade-off between these two contradicting goals.

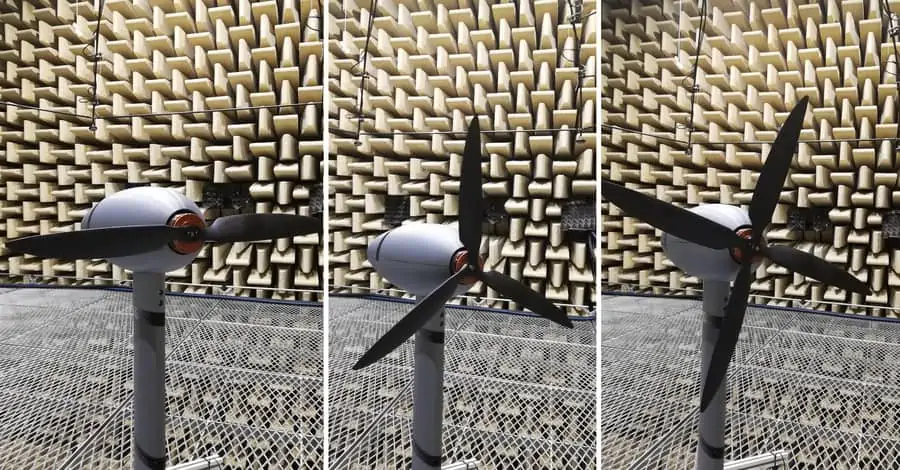

In total, four different propeller geometries were designed using various hybrid optimization schemes, then manufactured and tested at Mejzlik test lab (performance) and Resideo anechoic chamber (acoustics) in comparison with an off-the-shelf Mejzlik 18×6 MC propeller.

The results showed accurate performance and acoustics trends aligning with design analysis. These trends might be very useful for all multiroter developers. Detailed papers describing the outcomes and the comprehensive development process, together with discussion on each of the design and test phases are available here:

• Optimized Performance and Acoustic Design of Hover-Propeller

• Propeller Optimization Strive to Performance / Acoustic Trade-off

The next stage of the project will focus on the more complex optimization of the CR (Contra Rotating) configuration.