MicroLink Devices has announced that it has entered into an exclusive license agreement with the U.S. Department of Energy’s (DOE) National Renewable Energy Laboratory (NREL) to commercialize inverted metamorphic multi-junction (IMM) solar cell technology. The IMM solar cell architecture enables the manufacture of solar cells with very high efficiency as well as light weight, which are ideal for powering satellites and solar-powered unmanned aircraft.

MicroLink Devices has announced that it has entered into an exclusive license agreement with the U.S. Department of Energy’s (DOE) National Renewable Energy Laboratory (NREL) to commercialize inverted metamorphic multi-junction (IMM) solar cell technology. The IMM solar cell architecture enables the manufacture of solar cells with very high efficiency as well as light weight, which are ideal for powering satellites and solar-powered unmanned aircraft.

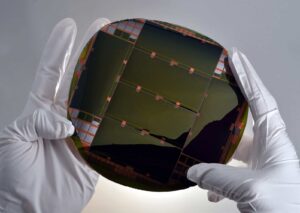

The world’s most efficient solar cells are multi-junction, which means that they use multiple light-absorbing layers to convert different wavelength ranges of the solar spectrum into electricity. Multi-junction solar cells based on germanium substrates have historically been used exclusively in very high-performance satellite applications. The IMM design is an innovative approach to further improve solar cell efficiency by integrating an optimum combination of three or more compound semiconductor materials. IMM multi-junction solar cells are manufactured by depositing thin layers of semiconductor on a substrate such as gallium arsenide (GaAs). A metamorphic buffer layer enables the growth of junction materials with ideal bandgaps for energy conversion such as indium gallium arsenide (InGaAs) that are not lattice-matched to the GaAs substrate. MicroLink Devices has demonstrated an efficiency of 32.3% under 1-sun AM0 using an IMM design.

IMM solar cells are synergistic with MicroLink Devices’ proprietary epitaxial lift-off (ELO) technology, which has been under development at MicroLink Devices for the past ten years. Using the ELO process, MicroLink is able to peel off thin layers of active solar cell material that were deposited on the GaAs substrate. Removing the substrate enables the fabrication of solar cells with exceptional light weight and specific powers greater than 3000 W/kg. The substrate can also be used multiple times to lower manufacturing costs. MicroLink’s ELO technology was sponsored by numerous US agencies including NASA, DARPA, the Air Force Research Laboratory, the Office of Naval Research, NAVAIR, Army Research Office, Army REF, CERDEC, and the Department of Energy.

“We are excited to be manufacturing solar cells and arrays using NREL’s IMM technology that have industry-leading performance as well as cost,” said Dr. Noren Pan, President and CEO of MicroLink Devices. “We have been working for more than a decade on the scale-up and manufacturing of this design, which enables us to provide very compelling solar solutions for powering high-altitude long-endurance (HALE) aircraft and space satellites.”

MicroLink Devices has previously announced a production contract to provide ELO multi-junction solar sheets to Airbus Defence and Space for use on the Zephyr S HALE platform. The Zephyr is a new class of unmanned air vehicle that operates as a high-altitude pseudo-satellite (HAPS) enabling affordable, persistent, local satellite-like services. The aircraft runs exclusively on solar power, and the Zephyr aircraft is at the forefront of the HAPS arena, holding world records with regards to absolute endurance (more than 14 days) and altitude (more than 70,000 feet).