Ulti-Mate Micro-D Circuit Connectors

Micro-D connectors, also known as microminiature D, are a particular subset of micro connectors, derived from the larger D-subminiature design. With a pitch of 1.27mm (0.05 in), the connectors are typically used in UAVs (unmanned aerial vehicles) and robotics applications where SWaP concerns are paramount. The robust construction and resistance to harsh environmental conditions also make the micro-D connector well-suited to space-grade technology.

Microminiature D Connector – Mechanical Characteristics

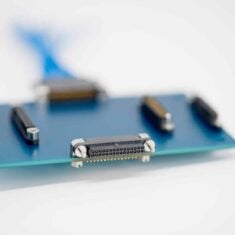

Omnetics Micro-D Connector

Micro-D connectors feature a high pin density, with one or more rows arranged in a parallel configuration. The D-shaped socket or plug provides reliable mechanical connection and ensures secure alignment and fit. The connector housing can provide EMI/RFI shielding, and due to its design is highly resistant to shock and vibration. Plugs and receptacles are typically fastened to each other via screws. Latching designs have also been developed for quick connection and disconnection, which may be vital when fielding drones and unmanned systems for battlefield or emergency response applications.

Micro-D Connector Termination Options

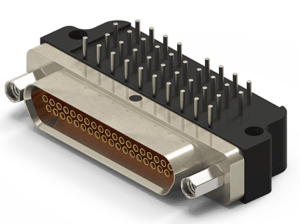

Nicomatic Micro-D Connector

Termination options for contacts in a micro-D connector include crimps, solder cups and IDC/IDT (insulation-displacement contact/insulation-piercing contact), and connectors can also be supplied with pre-wired contacts. Contacts may also be gold-plated for improved corrosion resistance. Connectors may be cable-mounted or feature through-hole, panel or surface mounting designs.

Many microminiature D connectors meet MIL-DTL-83513 military specifications, and higher grades for use in space environments are also available.