Two-stroke engines are designed so that a complete power cycle requires two movements of the piston (one up and one down) while the engine’s crankshaft completes one revolution.

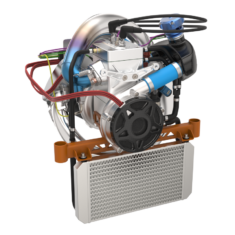

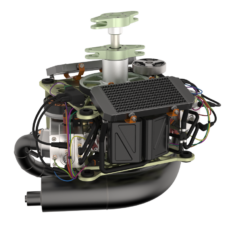

As they are smaller and lighter than four-stroke engines, 2-stroke engines are a common choice for UAV (unmanned aerial vehicle) propulsion. The high power-to-weight ratio provides the aircraft with a higher payload capacity.

2-stroke UAV engines also have fewer moving parts, and are thus easier and cheaper to manufacture and less complicated to maintain. They are however less fuel-efficient, producing greater levels of emissions as well as noise and vibration. Unlike 4-stroke engines, they do not have separate lubrication systems, and so engine oil must be pre-mixed into the fuel.

2-stroke drone engines may utilize fuel injection or a carburettor. In a carburettor, fuel is vaporized and mixed with air before being delivered to the engine cylinders. The engine’s throttle can open or close to vary the air intake and thus the fuel-air ratio.

Fuel Injected 2-Stroke Engines

With fuel injection, fuel is sprayed in close to the cylinder head, and is vaporized and mixed with air just before entering the cylinder.

Fuel injected two-stroke engines are harder to start, but are much more efficient, as the fuel-air mixture can be more precisely controlled. This is especially true of electronic fuel injection (EFI) engines, which use sensors to monitor engine conditions and adjust the fuel-to-air ratio accordingly.

Fuel Types

Two-stroke UAV engines may run on gasoline, methanol, or heavy fuels such as Jet A, Jet A1, JP-5 and JP-8. Heavy fuel engines are highly useful in military and maritime applications, where these fuels are commonly used to power other systems and thus sourcing an extra type of fuel is not required.