Aegis Power Systems, a manufacturer of power supply solutions for industrial, commercial and military applications, has written a technical article that explains the different cooling methods used in AC-DC and DC-DC power supplies.

All electronics generate heat and therefore are not 100% efficient. Each unit must have a way to dissipate excess heat in order to prevent damage and maximize reliability. This is done via thermal management, also simply referred to as cooling.

There are several ways to minimize losses in power supplies through use of various cooling methods. Efficiency and reliability are partly the result of a power supply unit’s designed cooling method.

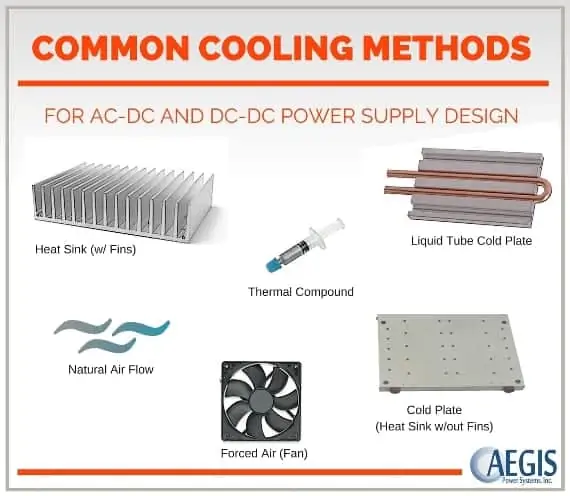

This overview delves into the most common techniques of conduction and convection cooling for AC-DC and DC-DC power supplies.

Heat Sink

Heat sinks are a type of conduction cooling, allowing heat transfer via direct contact with a cooler component of the unit.

Technically, heat sinks exist in two primary forms — those with fins and those without. However, engineering jargon generally refers to “heat sinks” as being those with fins and “cold plates” as being those without.

A heat sink with fins allows for a quick dissipation of heat due to increased surface contact with air and is frequently coupled with forced air cooling for maximum dissipation. Design considerations regarding space constraints usually limit this option to medium-large applications.

Cold Plate

Cold plates are a type of conduction cooling method where a thick metal plate is used to transfer heat away from a unit.

In many cases, cold plates are an effective thermal management solution where simplicity and space constraints are a concern. However, the application’s overall design must also account for a way to allow the heat to escape from the cold plate (natural air flow, thermal compound, and/or forced air may be used.)

Liquid

Liquid cooling refers to a special coldplate with an embedded tube running a closed loop of cool liquid. This can be water, but in our applications it is usually 50% water/50% glycol mix.

With liquid cooling, the base plate is kept at a very steady temperature so thermal transfer is most efficient. It’s a great solution for tight spaces where heatsinks and fans are not options. Liquid cooling is commonly used in aircraft, for instance, because of size and weight limitations. Ground vehicles also rely on liquid cooling, see our 600E power supply for electric vehicles for an example.

Although liquid cooling is the most efficient, there are downfalls in price and complexity. More materials and engineering time will be required to incorporate liquid cooling into a power supply design.

Thermal Compound

Thermal compound is not a stand-alone cooling method, but greatly aids in the transfer of heat from a heatsink or coldplate. Thermal compound, also called thermal paste or thermal grease, is a thermally conductive material that allows even adhesion between the unit and heatsink or coldplate component.

Natural Air Flow

Technically called convection cooling, natural air flow transfers heat away from a power device simply by surrounding the unit with cooler air. If the unit is enclosed, air vents may need to be included in the design to assist in circulation.

Natural air flow is often the least expensive thermal management option and certainly produces the best mean-time-between-failures (MTBF) rating due to the lack of additional mechanical components to create air movement. However, power supplies which rely on natural air flow for cooling are severely limited in their safe temperature operating range.

For heavy-duty applications such as aircraft, industrial robotics, shipboard, and other high energy devices, natural air flow is not an option to cool the associated power supplies.

Forced Air

Forced air is an upgraded version of the natural air flow solution to thermal management.

In this technique, one or more fans are built into the unit itself or specified elsewhere in the supported application’s design as a requirement to cool the power supply and thus achieve maximum rated output. Aegis’ HY2714A COTS DC-DC converter is an example of a power supply with customer-supplied forced air cooling.

One consideration when using forced air cooling is that fans also add to the inefficiency of a unit while simultaneously providing thermal management.

As a side note, fans may reduce the amount of internal dust build-up, contributing to the overall effectiveness and longevity of a power supply.

Which Cooling Technique Should I Use?

Each cooling technique provides a solution to thermal management for various power supplies. In most cases, the cooling system will be specified by customer requests during the initial design phase. In many applications, a combination of several cooling techniques may be used.

Global initiatives for improved energy efficiency have forced engineers to makes improvements in cooling power supplies. However, the progress for improvement has been slow. Aegis engineering manager, Mark Mason, weighs in saying, “99% efficiency may be achievable, but it may not happen in our lifetime. 100% is, of course, physically impossible.”

Although this reality is generally understood by all engineers, the push to achieve the best efficiency possible remains a driving factor for all industries.

For example, with the Aegis LMA501 DC-DC converter we have achieved the greatest efficiency of any Aegis unit thus far. With a 93% typical efficiency, this power supply allows energy to be consumed elsewhere in the supported application. In turn, that frees up budgeting for other portions of the overall design.

A number of factors go into deciding which cooling method your power supply design requires. Space, efficiency, cost, weight, and the amount of generated heat are all important considerations for thermal management.

Visit Aegis Power Systems for highly reliable and efficient power supplies and request a quote for a custom design.