Dymax, a leading manufacturer of UV/LED light-curable materials, has released the following case study detailing the use of SpeedMask® light-curable masking solution, with automated dispense and cure options, to dramatically improve manufacturing processes for military-grade PCBs (printed circuit boards).

The Challenge

A manufacturer specializing in PCBs for aerospace and defense applications wanted to improve its process efficiencies by increasing throughput with the automation capabilities of a masking process.

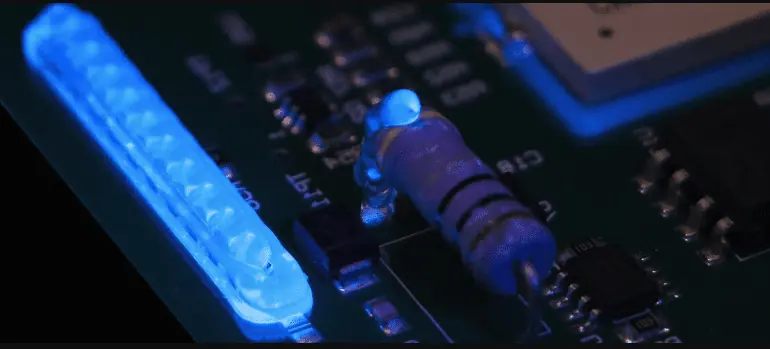

The customer’s original process involved masking military-grade PCBs in preparation for coating with a solvated conformal coating. Each board contained 28 plated mounting holes, 33 flush test points, and 8 through-hole connectors prior to coating. The customer’s application time was 19 minutes per board followed by racking the boards for air drying of the maskant. With five people, they were only able to process 22 PCBs per person, per day for a total of 110 PCBs.

The Solution

The Dymax team recommended a SpeedMask® light-curable masking solution with automated dispense and cure options.

The Dymax Team Territory Manager and Sales Partner met with the customer to review their process and understand their needs. The Dymax team looked at a UV solution with automated dispense and cure options as an alternative. They proposed Dymax SpeedMask 9-20479-B-REV-A and PVA Delta 8 Dispense Robot with FC100 dispense valve supported with Dymax UVCS 2.0 Conveyor with Fusion F300 UV curing lamps.

Results

The customer saw a daily process savings of 32 hours, freeing up four operators for other processes.

By switching to SpeedMask 9-20479-B-REV-A and the implementation of an automated process, the customer was able to cut the processing time from 19 minutes to apply only the maskant to five minutes to dispense and cure.

Altogether, Dymax helped the customer increase production output from 22 boards per person to 96 boards per operator and a 14-minute reduction in the process. The customer achieved daily process savings of 32 hours while freeing up four operators for other processes.