Entner Electronics has announced a new zoom block camera for embedded vision applications, such as unmanned vehicles and other robotic platforms. The UC-310 is a compact software programmable camera with proprietary electronics and a high quality zoom lens. The camera uses a rolling shutter STARVIS sensor to provide high sensitivity and dynamic range in visible light conditions.

Entner Electronics has announced a new zoom block camera for embedded vision applications, such as unmanned vehicles and other robotic platforms. The UC-310 is a compact software programmable camera with proprietary electronics and a high quality zoom lens. The camera uses a rolling shutter STARVIS sensor to provide high sensitivity and dynamic range in visible light conditions.

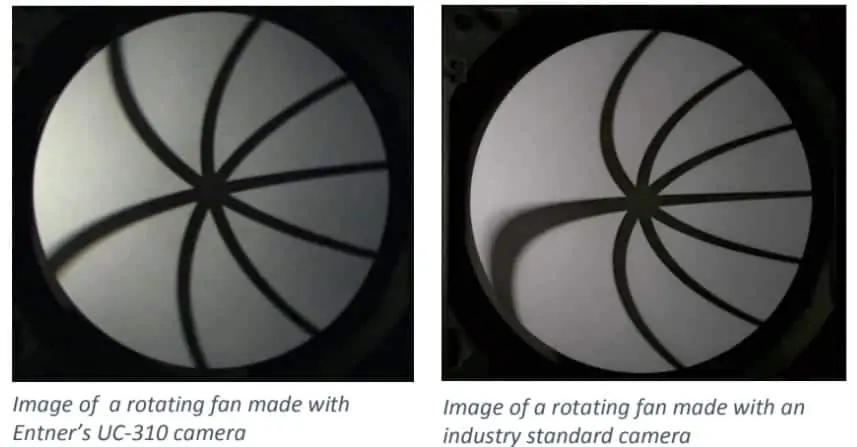

The read-out electronics are optimized to reduce the rolling shutter artifacts by a factor of 2 compared to other industry standard cameras. This allows integrators to benefit from the advantages of rolling-shutter sensors such as the use of compact, weight reducing optics.

Find suppliers of Cameras for Unmanned Applications >

To show the effects of Entner’s read-out electronics a rotating fan was recorded comparing Entner’s UC-310 camera with an industry standard camera in parallel. Both images are acquired at 1080p/60. Clearly visible upon comparing the images is the reduction of the ‘bending’ artifact when recording fast moving objects.

The UC-310 camera is compatible with the industry standard VISCA communication protocol to allow for hassle free upgrading of existing imaging systems. An LVDS and/or MIPI interface is available for integration with industry standard embedded computing platforms. Moreover all interface electronics are integrated in the camera to provide the most common interface standards like HDMI, USB and Ethernet. The benefit of this design approach is that the entire pipeline is controlled by the proprietary camera electronics resulting in an exceptionally low latency.

The onboard ARM-based processor offers the user the ability to integrate DSP functionality into the camera for applications such as object tracking, OSD generation, file management systems and much more. The Linux-based processor is open to the user or can be custom programmed by the Entner’s software development team.

“The UC-310 is the first member of a product family of zoom-block cameras for embedded vision. This is the next evolution in the industry of embedded vision and enables engineers to start developing their system upon receiving the camera without first having to solve the interface and processing part,” said Marco van Hout, Business Development Manager at Entner Electronics. “This approach has many benefits on the level of camera performance as well, as it greatly reduces the required integration efforts.”

A development kit containing the camera, a control-panel and physical access to all interfaces is available and allows developers to start testing the camera straight out of the box.