In this article, Sealevel Systems discusses the importance of optimizing Size, Weight, Power, Cost and Cooling (SWaP-C2) in the design process of embedded computing systems and electronic components for unmanned platforms.

As aerospace and defense technologies are becoming more and more complex – in terms of capabilities and feature/component density – the successful deployment of new equipment requires a detailed, step-by-step design approach. There are countless factors that go into this design process, but optimizing SWaP-C and/or SWaP-C2 is the most critical.

What is SWaP-C?

SWaP-C is an acronym for Size, Weight, Power, and Cost, most often referring to embedded computing and/or electronic components. Initially, the acronym was SWaP – for size, weight, and power – which is why the “a” is between the “W” and “P.”

Lowering and optimizing SWaP-C is a goal for every industry and application of embedded computing, but the acronym is mostly used in the context of defense and aerospace industries. Design decisions are often focused on making a component smaller, lighter, more powerful, or lower in cost. Realizing even one of these goals is usually enough to merit a new component. Ultimately, the goal is always to make the lightest, most powerful system, with the smallest possible footprint, for the lowest cost.

Military unmanned ariel vehicle (UAV) platforms provide a good illustration of SWaP-C requirements. In the most basic sense, military UAVs are remotely or autonomously controlled sensor platforms for information gathering or surveillance. As the information-gathering components become more complex – video or still image cameras, FLIR cameras, mapping imagers – they require more processing power. If the UAVs are remotely operated, they must include data communications networking hardware. Further, the entire platform must be designed to meet the environmental conditions of the area of operation – high altitude, extreme hot or cold temperatures, precipitation, etc. All of this is to say that military UAVs are incredibly complex systems of interconnected components. The range and capability of these platforms are, ultimately, limited by size and weight; fuel costs – whether battery power, liquid fuel, or solid fuel – increase as the size and weight of the UAV increase. Therefore, by optimizing the SWaP-C of the individual components, the functionality of the entire system is increased.

Introducing SWaP-C2

The Department of Defense has expanded the acronym to SWaP-C2 – Size, Weight, Power, Cost, and Cooling. As embedded computing systems and electronic components continue to shrink and optimize the standard SWaP-C characteristics, thermal management concerns have increased.

Placing more components in smaller spaces generates more heat, with less flow space. Fans are a common solution for heat dissipation, but the introduction of moving parts increases the opportunity for failure. Thermal management of rugged systems is better served by incorporating heat sinks or heat pipes, and mechanical enclosures employing conductive materials and fins or rods along the device exterior to manage heat.

Achieving SWaP-C2 with Sealevel

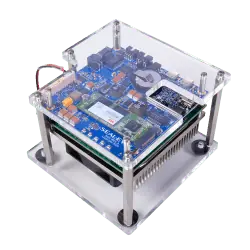

By leveraging PCIe/104 and COM Express technology, Sealevel’s team is able to engineer application-specific functionality. PCIe/104 stacks vertically while COM Express allows for the carrier board size to adapt horizontally to conform to footprint restrictions.

With the added requirement of meeting cooling specifications, Sealevel is able to utilize an extensive library of thermal management techniques, beginning with component selection and placement all the way through thermal simulation and testing.

Sealevel’s 12009 COM Express Type 6 Carrier Board maximizes I/O and processing support while maintaining the smallest possible footprint for a Compact Type 6 carrier board. At 95 millimeters square, the 12009 is identical in size to the COM Express module and features Gigabit Ethernet, USB 3.0, and USB 2.0 – prevalent in vision systems technology.

Sealevel’s 12009 COM Express Type 6 Carrier Board maximizes I/O and processing support while maintaining the smallest possible footprint for a Compact Type 6 carrier board. At 95 millimeters square, the 12009 is identical in size to the COM Express module and features Gigabit Ethernet, USB 3.0, and USB 2.0 – prevalent in vision systems technology.

Optimizing SWaP-C and/or SWaP-C2 is a delicate balancing act, that requires careful consideration. Often, seemingly minor design changes can affect a device or system’s performance. Now more than ever, SWaP-C/SWaP-C2 must be managed and optimized in defense and aerospace applications to improve operational efficiency and logistics, increase mission life, and reduce the total cost of system ownership.