The CRP Group, specialists in technical materials for 3D printing and Additive Manufacturing, have announced that Windform XT 2.0 has passed ESA screening outgassing tests in accordance with ESA TEC-QTE 7171 (based on ECSS-Q-ST-70-02C).

Metallized coated and uncoated samples of Windform XT 2.0 have been tested in the μVCM facility of the TEC-QTE laboratory at ESA/ESTEC, Noordwijk, Netherlands. The ESA outgassing tests can be considered passed for both coated and not-coated samples and they respond to the general outgassing criteria based upon the micro-VCM test (as defined by ECSS-Q-ST-70-02C). The general requirement for materials screening outgassing is RML<1.0% and CVCM < 0.1%.

The development of Windform materials has helped to advance additive technologies, and now allows for new and custom-made solutions for the space industry which were previously impossible to implement with traditional manufacturing methods.

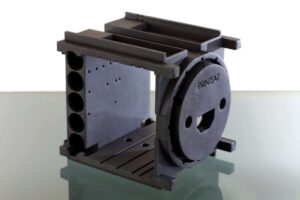

Windform Additive Manufacturing is suitable for a number of applications in which a highly durable material is required; the polyamide-based material can also be processed with high precision CNC machining.